BIOMASS Briquette Making Machine

Biomass Briquette Making Machine

The Biomass Briquette Making Machine is designed to produce high-quality wood briquettes using low-cost raw materials such as sawdust, rice husk, corn cobs, peanut shells, cotton stalks, tree branches, and almost any kind of agro or forestry waste. The resulting briquettes are high in density, making them an excellent source of fuel.

The Biomass Briquette Machine converts agricultural and forestry waste into compact briquettes. Briquetting essentially means compressing loose biomass material into a denser form, making it easier to transport, store, and use while significantly increasing its calorific value.

This machine produces high-quality briquettes without the need for any binder or chemical additives. It works by compacting raw material with the help of a high-pressure mechanical punch. During this process, the temperature rises naturally, allowing the raw material to release lignin and other natural adhesives. These act as a binding agent, holding the briquettes firmly together. This process is known as binder less technology.

Advantages of Biomass Briquettes

Excellent source of fuel with high calorific value.

Easy to produce from agro and forestry waste.

No harmful emissions or effluents are released during briquetting.

Provides consistent combustion.

Compact in size, making them easy to store, handle, and transport.

Available Sizes

40 mm, 60 mm, 70 mm, 75 mm, and 90 mm

Available Spares

Gun Metal Bush

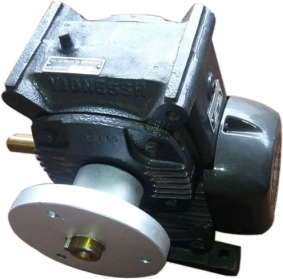

Gears and Gearboxes

Die Set

Raw Materials Used

The final bio-fuel briquette is made using advanced Biomass Briquetting Machines. Almost all types of agro-forestry waste can be used, including:

Sawdust

Groundnut shells

Wood chips

Maize stalks

Soybean stalks

Broomcorn stalks

Cotton stalks

Grape stalks

Peanut plants

Sunflower stalks

Bamboo sawdust

Bagasse

The specific density of biomass briquettes is as high as 1200 kg/m³, compared to 60–180 kg/m³ of loose biomass. Compared to wood or coal, biomass briquettes have lower ash content and lower moisture levels, making them more efficient and eco-friendly.